Variable refrigerant flow (VRF) is an efficient commercial HVAC solution in cold climates

Variable refrigerant flow (VRF) is one of the most efficient options currently available for electrifying commercial HVAC in cold climates–especially if installed correctly in the right types of buildings.

In a pilot study for ComEd Customer Innovation, we looked at the effectiveness of cold-climate VRF in the ComEd service territory.

What we learned

VRF can reduce energy use and carbon emissions in cold climates for commercial and multifamily HVAC when installed correctly.What surprised us

Some early (and avoidable) installation issues were severe enough to require replacing the equipment.What's next

Programs should add incentives and trainings to inspire VRF adoption.The market for VRF in cold climates

In Phase I of the pilot, we assessed the existing market for VRF in ComEd's service territory. This included product reviews; interviews with stakeholders at each level; reviews of energy efficiency programs in ComEd’s service territory and nationwide; and estimates of the size, energy savings, and cost-effectiveness of VRF.

Generally, knowledge of VRF as a reliable cold-climate system is still lacking among key market actors. The buildings that do have VRF installed tend to share a common characteristic: they are large buildings with multiple heating and cooling zones that benefit from a precise HVAC system.

However, VRF is also common in retrofits of smaller, older buildings, especially historic buildings not originally designed for air conditioning.

| Benefits of VRF systems | |

|---|---|

| Energy + Carbon Emissions | Operational + Non-Energy Benefits |

|

|

Building owners and operators who decide to adopt VRF are often motivated by a combination of both energy and non-energy benefits. Both are significant and work together to drive VRF adoption.

Findings from our field demonstration

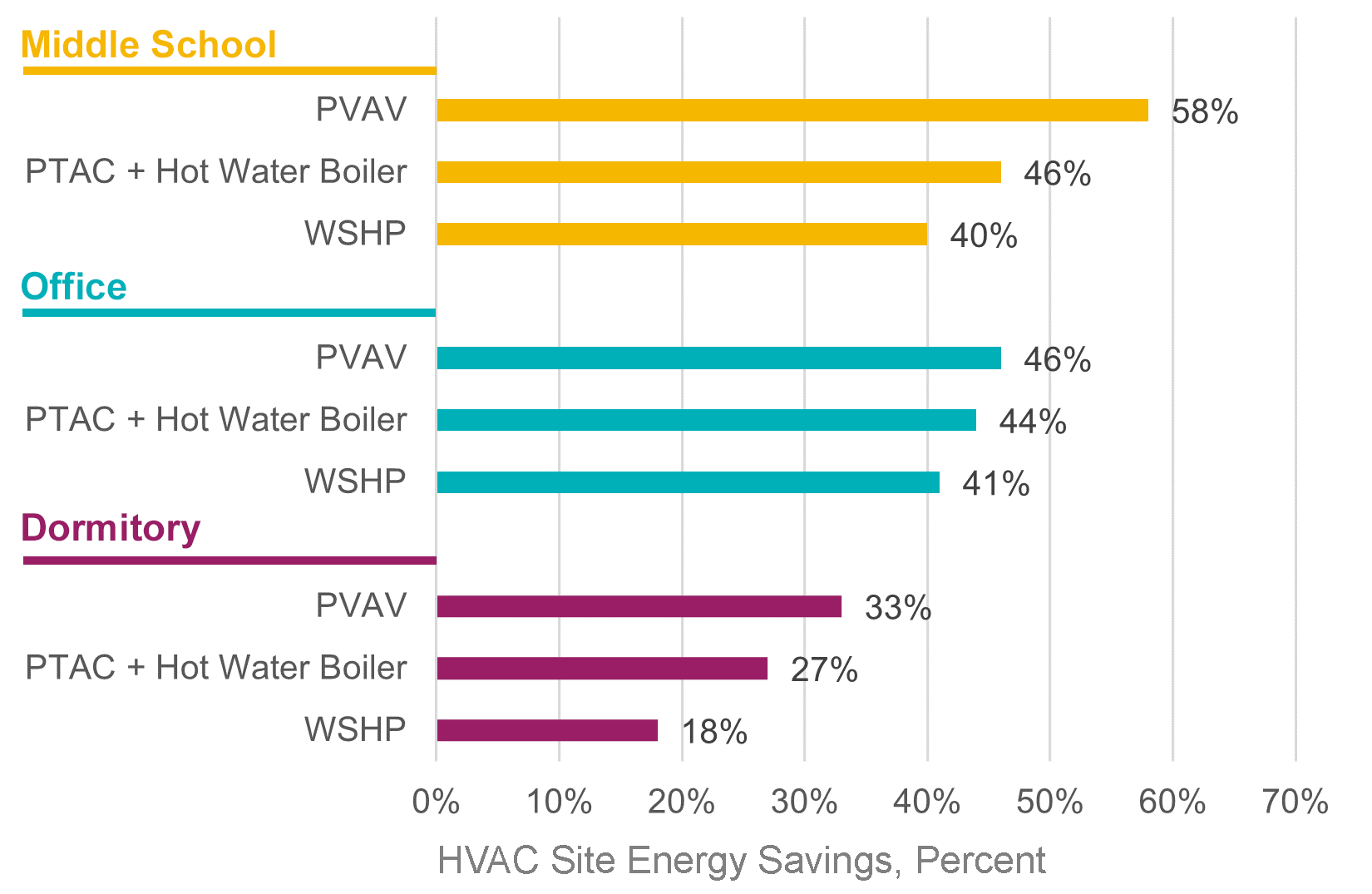

Phase II of this project included a field demonstration of VRF in three sites: a middle school, an office, and a dormitory.

Effectiveness and cost savings ✅

In all three sites, we observed that the VRF system maintained a comfortable temperature range throughout the year. On the coldest days of the year, some zones dropped slightly below 70° Fahrenheit. Qualitative interviews with operators confirmed that the system generally performed well throughout the year.

Most of the savings are due to reduced usage of natural gas, and most systems have slight electric demand penalties when operating in heating mode. VRF saves the most energy at part load, where it can take advantage of its highest efficiency.

Cost savings were less than the energy savings, mostly due to the low cost of natural gas compared to electricity. To illustrate an example from this study: compared to a traditional VAV system, cold-climate VRF would save over 16% of building HVAC energy cost in a year.

Reduced emissions ✅

VRF also reduces greenhouse gas emissions compared with other HVAC systems. Emissions impacts vary in the same proportion to the utility cost savings. These will increase significantly as more renewable energy is added to the grid.

It’s important to note that some of the emissions savings may be offset by the potential leakage of refrigerants, which can have significant climate impacts. However, this risk will be reduced as the refrigerants used in VRF systems shift to newer, climate-friendly alternatives starting in 2026. Either way, the careful management of refrigerants is an important element to consider in all programs as we scale VRF installations.

Installation issues ⚠

Unfortunately, in some cases, early installation issues were severe enough to require early equipment replacement. VRF refrigerant lines do not follow the same rules as traditional air-conditioning lines or water piping. This can add complexity to an installation and lead to poor-quality installations. Installer and designer training—ideally under the guidance and oversight of a manufacturer—are key to making a VRF project successful.

Recommendations:

- Design incentives to make VRF the top choice in the right building types. Some jurisdictions such as Illinois now allow energy efficiency incentives for fuel switching. VRF is likely to be a good choice for many buildings, such as K-12 schools, high-rise multifamily buildings and dormitories, hotels, and retail buildings.

- Partner with VRF manufacturers and local distributors. For building sectors that are prime candidates for VRF, program outreach staff can be trained to understand typical market concerns about VRF and the top strategies for ensuring a successful project.

- Ensure service providers in the territory have the proper training, experience, and incentives. VRF installations are dependent on quality installation more than other HVAC systems. Installer training plays a big part in ensuring that quality. Programs should consider ways to ensure successful outcomes for projects installing VRF systems.

- Streamline incentives to reduce VRF first costs. VRF systems are premium HVAC systems which carry higher first costs when compared to basic HVAC alternatives.

- Provide education for building operators with VRF systems. VRF is an effective, efficient option that requires its users to understand it. Connect building operators with manufacturer or contractor training and consider other education options to make sure operators can get the most out of their systems.

More resources:

Find more information on our VRF studies and publications.